ABOUT US

Hexaplast is a world class manufacturer and exporter of various type of Ball Valve Testing Machinery. We bring the innovation with perfection. We offer best in class machinery solution that includes polymers testing machine, Ancillary machinery, Different types of Plastic testing equipment, Plastic impact testing machine, Rubber testing machine, Woven sack & Raffia quality checking machines, as per industrial applications. We create top notch machinery that increase the productivity and decreases the production cost.

Muffle Furnace / Ash Content Tester

Technical Specification

- Size of muffle furnace : 4” X 4” X 9” deep.

- Heating Load : 2 KW.

- Temperature Range : Ambient to 1000°C.

- Temperature Controller : Digital micro controller

- Resolution : 1°C & Accuracy of ±1°C.

- Table Top Model

- Power Supply : 1 Phase, 230 VAC, 50 HZ

- Paint : Powder coating

Accessories :

- Silica Crucible 50ml

- Bunsen Burner

- Desicutter With Plate 4″

- Tripod Stand With Mash

- Tong 6 Inch

- Sulphuric Acid 500 ml

Usage/Purpose/Application of Muffle Furnace:

Muffle Furnace is used to determine if a material is filled. The Muffle Furnace result is expressed as % ash. The total ash content equals the weight of the ash divided by the weight of the original sample multiplied by 100%.

Vacuum Oven

Specifications:

- Size of inner S.S. chamber: 24 inch X 24 inch X 24 inch.

- Temperature controller: Digital PID controller with

- Range up to 300 °C and accuracy of ± 0.5 °C

- Heating load: 2.5 kW.

- Air circulation: Radial fan.

- Tray: 2 numbers.

- Paint: Powder coating

- Power: 1 Phase, 230 V, 50 H

Usage/Purpose/Application of Vacuum oven:

- A vacuum oven, unlike general purpose oven, dries samples without oxidation and residue. A vacuum oven is an ideal choice; where, samples are dried in absence of atmosphere (vacuum condition) or

presence of inert atmosphere (Argon, Nitrogen, Clean Dry Air). A vacuum oven has two ports; Vacuum Port with needle valve to connect the vacuum pump and another is Inert Gas Port with a needle valve to connect with the gas cylinder. A microprocessor PID controller is fitted in vacuum oven to control the temperature inside the chamber. Analog vacuum gauge displays vacuum level. Temperature thermostat keeps the unit safe if temperature exceeds beyond set degree of vacuum oven. - The purpose of using vacuum oven is to eliminate surface reactions (condensation or oxidation) on the parts inside the oven. While determining the drying process, it is mandatory to define the

chamber size, vacuum pump capacity and level of desired vacuum, and time to achieve this vacuum level.

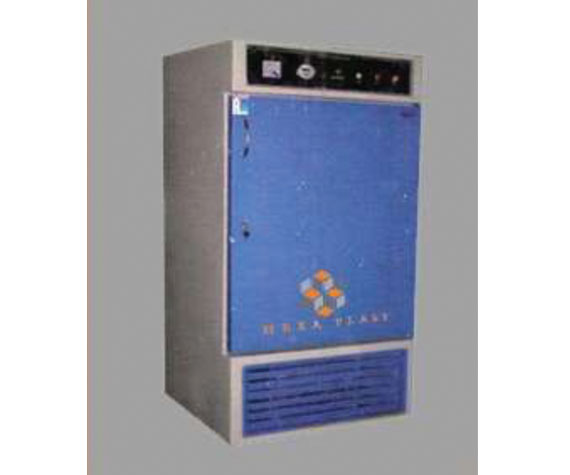

B.O.D. Incubator

Specification:

- Inner chamber made out of S.S 304

- Outer chamber made out of M.S sheet duly powder coated.

- Working chamber size: 18” X 18” X 18”

- Gap between both chambers filled with CFC free PUF insulation.

- Highly efficient refrigeration system with Eco-friendly refrigerant.

- Temperature range: 0 -45*C

- S.S made fins type tubular heater for stable temperature.

- Microprocessor based PID temperature controller with pt 100 sensor for accurate temperature controlling.

- S.S rod made shelves.

- Solid state relay for over current protection.

- Air cooled condenser.

- Forced air circulation for uniform temperature.

- Automatic Fluorescent light for illumination purpose inside the chamber.

- Castor wheel for easy move ability

Usage/Purpose/Application of B.O.D. Incubator:

- These incubators are also called low temperature incubators.

- The BOD incubator provides the required temperature for the growth of microorganisms and allows to perform the BOD testing.

- Cooling of the incubator can be achieved either by using refrigeration principle or by Paltrier element.

Hot & Cold Water Bath

Specification:

- Capacity: 100 liters approx.

- Working Area: 450 (L) X 500 (W) X 450 (H) in mm.

- Temperature Range: Ambient plus 20°C to 95 °C.

- Accuracy: +/‐ 0.5 °C.

- Temperature controlling system: PID controller with thermostat.

- MOC Inner: SS‐304, Outer MS Powder coated.

- Door opening: 1 Layers.

- Water level controlling: Auto + Safety.

- Water circulation : With Heavy duty pump (mention make)

- Heating Load: 4 Kw (Proposed. You may recommend your design)

- Supply : 230 VAC/50 Hz

Usage/Purpose/Application of Hot & Cold Water Bath:

- Bath is a unique test cabinet designed to detect the change in the physical characteristics of material and to ascertain the actual working life of test samples at elevated temperature.

- It is used to incubate samples in hot water/cold water at high/low temperatures required in plastic and Pipe industries.

- The Water Bath comes with motorized stirrer for maintaining constant heating/cooling efficiency.

Hot Water Bath

Specification:

- Size of the inner : 304 S.S. Bath: 48”X 36”X 18” (Other size also available as per requirement)

- Temp. controller : +/- 1.0°C.

- Range : Ambient to 95° C

- Circulation : Through C.G make Pump.

- Load : 8 kw.

- Paint : Powder coating.

- Power : 440 V AC, 3 Phase , 50 Hz

Usage/Purpose/Application of Hot Water Bath:

- Bath is a unique test cabinet designed to detect the change in the physical characteristics of material and to ascertain the actual working life of test samples at elevated temperature.

- It is used to incubate samples in hot water at high temperatures required in plastic and Pipe industries. The Water Bath comes with motorized stirrer for maintaining constant heating efficiency.

Cold Water Bath 48"

Specification:

- Size of the inner 304 S.S. bath: 48”X 36”X 18”.Outer M.S body (Other size also available as per requirement)

- Temperature controller: Auto tune PID Controller

- Range Ambient to 15 degree and accuracy of ± 1 deg C.

- Circulation: Through C.G make Pump.

- Compression: kiloskore make.

- Paint: Powder coating.

- Power : 230 V AC, 1 Phase , 50 Hz

Usage/Purpose/Application of Cold Water Bath 48″:

- Bath is a unique test cabinet designed to detect the change in the physical characteristics of material and to ascertain the actual working life of test samples at elevated temperature.

- It is used to incubate samples in cold water at low temperatures required in plastic and Pipe industries. The Water Bath comes with motorized stirrer for maintaining constant cooling efficiency.

Cold Water Bath 60”

Specification:

- Size of the inner 304 S.S. bath: 48”X 36”X 18”.Outer M.S body (Other size also available as per requirement)

- Temperature controller: Auto tune PID Controller

- Range Ambient to 15 degree and accuracy of ± 1 deg C.

- Circulation: Through C.G make Pump.

- Compression: kiloskore make.

- Paint: Powder coating.

- Power : 230 V AC, 1 Phase , 50 Hz

Usage/Purpose/Application of Cold Water Bath 60”:

- Bath is a unique test cabinet designed to detect the change in the physical characteristics of material and to ascertain the actual working life of test samples at elevated temperature.

- It is used to incubate samples in cold water at low temperatures required in plastic and Pipe industries. The Water Bath comes with motorized stirrer for maintaining constant cooling efficiency.

Resistance to Dichloromethane

Specification of Resistance to Dichloromethane:

- Stainless steel container

- Dimensions (Inner) :400 mm X 400 mm X 200 mm

- Dichloromethane level indicator

- Grating should be 1 cm above the bottom of container

- Lid should be provided to limit the evaporation

- Thermostat: to maintain temp. at 15 ± 0.5 0C

- Cooling device should be provided

- Stirrer to homogenize the temp

- Pair of Pincers should be provided for handling specimen

- Hood with fume extraction system

Hot Plate

SPECIFICATION:

- Temp. is controlled with PID programmable temperature.

- It has a controller and energy regulator.

- Digital Hot Plate comes with S.S. plate with uniform necking arrangement.

ATTACHMENT:

- Petri Dish: 100 mm.

- Silicone Oil: 100 ml.

INSTALLATION:

- Unpack the material and see if there is any damage.

- Give the 15 A, 230 V AC, 1Phase supply.

APPARATUS:

- Hot Plate is made up of 8inch S.S. plate.

- It consists of voltmeter, voltage regulator, temperature & timer programmable controller & main switch.

- A censor has been mounted, so that actual temperature of the hot plate can been seen.

OPERATING PROCEDURE:

- Set the temperature required for your specific test specimen

- Rate of increase in temperature can be controlled by voltage regulator (sun bin). Voltage regulator can be set for higher and lower temperature rise.

Instrument Setting:

- SET – This key is used to set the required temperature & time.

- UP & DOWN – Both keys are used to increase & decrease the parameters.

- ENT – This key is used to store the values.

Usage/Purpose/Application of Hot Plate:

- Hot plate (film shrinkage tester) is used for film or packing industries.

- The hot plate is been heated with oil at shorten temp. given in standard.

- Sample of film of given length and diameter is been cut and measure.

- The sample is been put in hot plate for certain on period of time.

- The sample in been measure again after taking out from hot plate.

- Get result by measurement.

CONTACT US

ADDRESS

Plot No : L-4126/1, Phase IV, G.I.D.C. Vatva,

B/h. New Nirma, Vatava, nr. Nika tube cross Road, Ahmedabad, Gujarat 382445